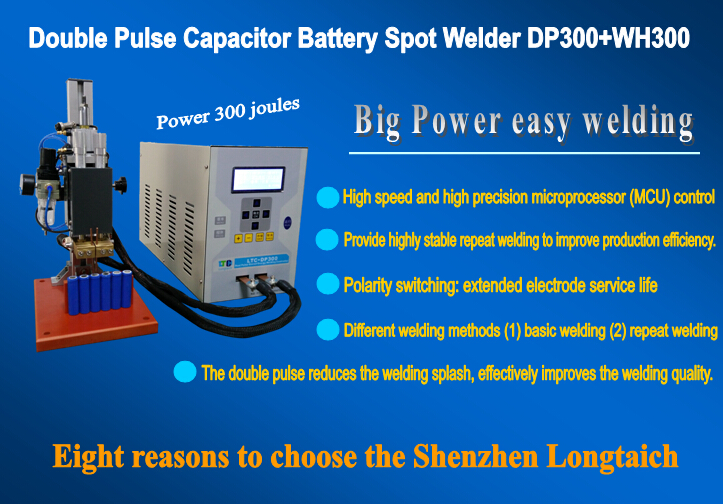

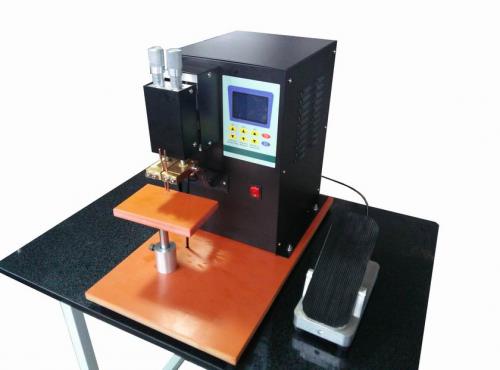

Power Tool Battery Pack Spot Welder LTC-DP300

Product Description

Battery Spot Welder LTC-DP300. Professional Battery Spot Welding mahcine in China.

Power Battery Packs Spot Welding Machine Manufacturer | Longtaich.com

Watch the welding videos, please click the YOUTUBE URL:

https://m.youtube.com/watch?v=g6Pex8aMp0o

https://m.youtube.com/watch?v=06yRHcDIqDk

Instruction

DP300 battery assembly welding power source adopts Japan the most advanced welding technology, is the present domestic advanced level of high performance precision resistance welding machine, designed for the production of high-end mobile phone batteries, power batteries, digital batteries, nickel metal hydride, nickel cadmium battery, such as needed to design, also can welding parts, LED lights, electronic components, feet, capacitance, etc.

DP300 series precision resistance welding power source is the IGBT inverter technology, microcomputer control technology and modern power electronic technology development of a new type of power supply. Time control millisecond precision, control response and control precision is greatly increased; Significantly improve welding technology; Advanced technology and equipment has advantages of small, energy efficient and a series of; Microcontroller (MCU) and the using of electronic technology makes the equipment with outstanding features of modern equipment, including digital control, monitoring, fault diagnosis and protection, data transmission, etc., equipment is fully functional, flexible, convenient, adaptation of wide.

The main technical characteristics:

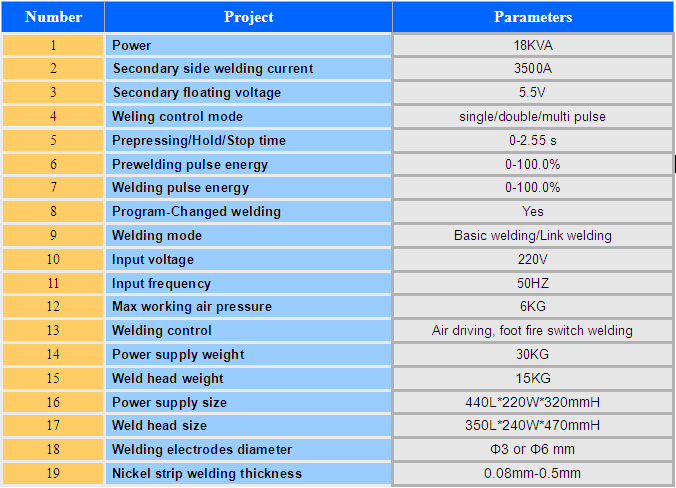

l high speed and high precision (MCU) microprocessor control, provide highly stable repeat welding.

l high speed welding: quick start and high-speed switch polarity to reduce the temperature effect so that the welding surface is clean and beautiful.

l polarity switch: inhibition of asymmetric effect for uniform two-point welding strength and prolong the service life of the electrode.

l Welding the response speed.

l blu-ray 19264 LCD screen display, graphical display of the current work status, friendly interface, welding pulse graphics functions improve the ease of debugging observation.

l double pulse reducing welding spatter, improve the welding quality.

l Two kinds of different welding method (1) the average spot welding; (2) continuous welding.

l Built-in welding counter, can do all its solder joints.

l Data storage block using EEPROM, no battery life issues, to the use of welding procedure every time you boot.

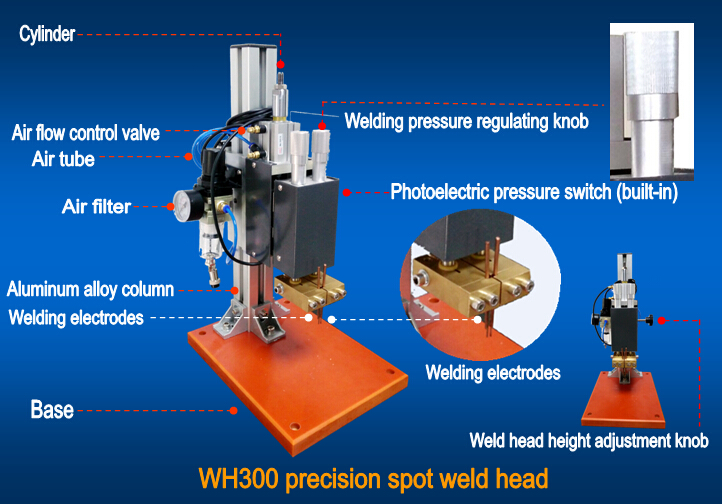

l Compatible with welding of pressure switch and no welding machine, welding head pressure switch.

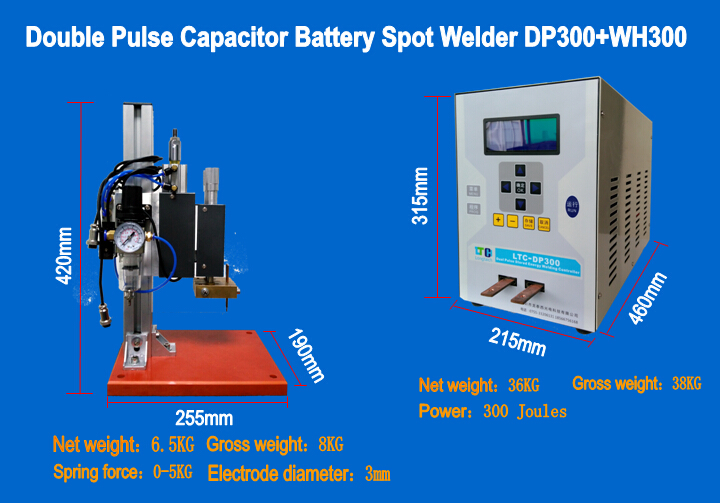

l Preloading time, pressure maintaining time continuous adjustable from 0 to 2.55 seconds.

l pressure discharge switch can use photoelectric switch, non-contact, durable.

Deutsche

Deutsche Español

Español français

français italiano

italiano português

português 日本語

日本語 한국어

한국어 العربية

العربية русский

русский bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt