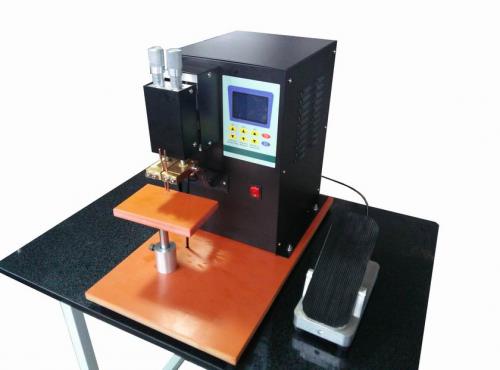

Inverter DC Battery Pack Spot Welder IP-5000A

Product Description

Inverter DC Weld Power Supply Micro Spot Welder IP-5000A

YOUTUBE video showroom:

https://youtu.be/Klemdg8l4SY you can watch the battery pack welding video

Longtaich (www.longtaich.com ) IP-5000A is a professional DC inverter Welding

power supply , work with it’s battery pack welding head(double dot), or sheet

and wire welding head(single dot), high-speed spot welding, less welding

temperature, good for battery cells and metal sheet and wires, is widely use in

manual or automatic spot welding machine, usually spot weld 18650 lithium

battery packs, e-bike battery packs, electric tool battery packs rebuild and

assemble, other thin sheet and micro wires, etc. The IP-5000A will give you a

high-quality spot welding.

Functional features:

1. 4kHz high frequency inverter control is beneficial to high speed and high

quality welding control.

2. stage power on function is used to overcome the coating problem of welding

workpiece and adapt to various process requirements.

3. t has the function of current slow rising and current decreasing, which is

helpful to restrain spatter in welding

4. The switch of 8 welding specifications is helpful to change welding

parameters quickly according to different welding requirements.

5. The LCD with blue light LCD20x4 line displays a variety of welding

information and welding parameters, which is convenient for the confirmation of

welding results.

6. It has two section current monitoring and comparison function, welding

abnormal alarm, comparing welding results with equipment parameters, and

judging whether it exceeds the setting

7. After the value, determine whether the output is normal (GO) or abnormal

(GN) display and signal.

8. imported IBGT module full bridge control welding, welding quality and speed

is not ordinary energy storage welding energy ratio.

9. data storage using EEPROM, no battery life problem, every boot back to the

last use of welding procedures.

10. the sound and light alarm of abnormal current can effectively prevent

the occurrence of false welding and false welding

11. with fault self diagnosis function, display the corresponding fault

point, convenient for maintenance

Main technical parameters:

Serial number parameter item IP-5000A

1 rated power: 10KVA

2 welding current: 5000A (300A-5000A adjustable)

3 load duration: 20%

4. Welding control mode: imported IGBT module control,

5 inverter frequency (kHz): 4kHz

6 floating voltage: 10.8V

7. Slow rise and slow decrease of current has the function of slow rise and

slow decrease of current

8 welding specifications: 8 groups

9 input voltage: 3-phase AC 380V ± 10% 50

/ 60Hz

Characteristics of equipment:

1. The welding (load) current is controlled by the closed-loop hardware

circuit, which is conducive to high-quality welding control.

2. 4kHz high frequency modulation inverter control is conducive to high-speed

and high-quality welding control.

3. The use of 2-stage welding function is conducive to overcome the coating

problem of welding workpiece and adapt to various process requirements.

4. The function of slow rise and decrease of current is beneficial to restrain

spatter in welding. The switching of eight welding specifications is conducive

to the rapid transformation of welding parameters according to different

welding requirements.

5. A variety of welding information and welding parameters are displayed in the

20 * 4 line LCD, which is convenient for the confirmation of welding results.

6. It has the display and signal of normal output (go) or abnormal (GN) after

comparing the welding results with the parameters of the equipment and judging

whether it exceeds the set value.

Other parameters:

1. Equipment name:

Inverter DC Weld Power Supply Micro Spot Welder IP-5000A

2. Model: IP-5000A (inverter welding control device)

3. Input power supply: 3-phase AC 380 V ± 10% 50 / 60 Hz (If need the power of

220 V will decrease, which needs to be customized)

Attention: please confirm the input power of the machine to avoid danger!!

4. Service conditions:

Operating temperature 0 ºC ~ + 50 ºC humidity: below 90%

5. Maximum output current: 5000A (short circuit maximum current).

6. Welding time setting range:

1) Preloading time sque: 0-999ms (MS)

2) Slow current rise U1: 0-49ms (included in current I1)

3) Current I1:: 0-99ms

4) Current ramp D1: 0-49ms

5) Cool: 0-99ms

6) Current slow rise U2: 0-49ms (included in current I2)

7) Current I2:: 0-99ms

8) Current ramp D2: 0-49ms

9) Hold time: 0-999ms

7. Control frequency: 4kHz

8. Control mode: primary current detection, hardware closed-loop control.

9. Cooling mode: forced air cooling

10. Maximum utilization rate: 20% (5000A)

11. Welding transformer output: maximum current 5000A, no-load voltage 10.8V

12 welding condition (mode) setting: 8MODE(MODE 0,1,2,3,4,5,6,7)

13. Welding current detection function:

Set current ± 3 to ± 9%. When the actual welding current is within the set

current, "GO" is output, and "NG" is output when the setting

current is exceeded. If ± n is selected, the alarm will not be monitored

14. Welding current setting range

1) CURRENT 1 : 800~5000A

2) CURRENT 2 : 800~5000A

15. Output mode of judgment result (I / 0 connectors)

Open collector output (DC 30V 200mA max)

16. Dimensions: IP-5000A

195(W)*280(H)*450(D)mm

17. Weight: IP-5000A = 19kg

YOUTUBE video showroom:

https://youtu.be/Klemdg8l4SY you can watch the IP-3000A battery pack welding video

Deutsche

Deutsche Español

Español français

français italiano

italiano português

português 日本語

日本語 한국어

한국어 العربية

العربية русский

русский bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt