Method of Spot Welding Nickel Tabs for 18650 Lithium Battery

Spot welding the lead-in piece and connecting piece on the battery is often OK, but the people who spot welding the lead-in piece and connecting piece on the 18650 lithium battery are very human. The 18650 lithium battery spot welding lead-in piece is complex but simple. The function of the lead-in piece and connecting piece is to connect and output the performance of 18650 lithium battery, which is mainly reflected in various lithium battery groups. The main methods of spot welding lead-in piece and connecting piece are as follows :

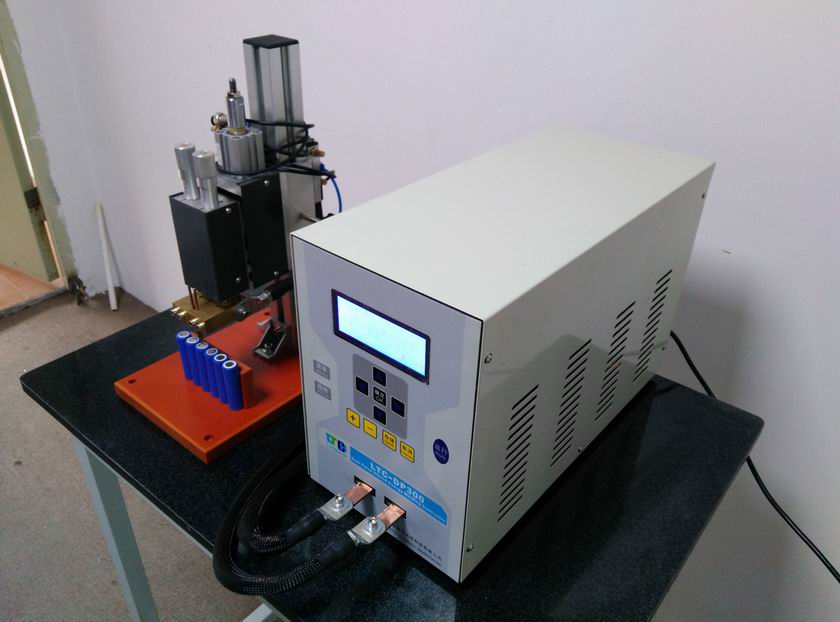

1. Press the power switch of double head pulse spot welder to the "on" position to turn on the power.

2. Confirm that all parameters of the battery spot welding equipment have been debugged, and prepare materials and relevant tools according to the right parameter setting table.

The tools can be: double head spot welding machine, filigree knife, pressing fixture, hexagon wrench.

When debugging the parameters of the battery spot welder, it must be confirmed with the quality engineering, and it can be operated only when it meets the requirements.

When spot welding 18650 lithium battery, attention must be paid to the spot welding tension, which should be within the quality inspection range.

3. Pick up a battery, with the bottom of the negative terminal facing up, take a lead out piece, with the round hole end of the lead out piece outside, and spot weld the lead out piece in the middle of the negative terminal of 18650 lithium battery.

4. Turn the lithium battery pack to the inside, take a connecting piece, place the connecting piece on the top of the leading piece, spot weld the connecting piece in the middle of the negative pole of the battery, and form a line with the leading piece.

5. Pick up the other battery, with the bottom of the negative terminal facing up, and spot weld the exposed end of the connecting piece of the first lithium battery pack to the middle position of the bottom of the negative terminal of the second battery.

6. Place the series spot welded battery pack on the pressing fixture, press the battery pack toward the middle with force, so that the two batteries are closely combined, and the two batteries are in a straight line.

7. After the pressed battery pack flows into the next work station, clean up the work table and turn off the power switch of the spot welder.

Points for attention of 18650 lithium battery spot welding lead-out piece and connecting piece:

1. The specification of outgoing piece shall conform to the BOM specification of materials.

2. Solder joints shall be free of defects such as missing welding, faulty welding, explosion, obvious burr, etc.

3. The number of solder joints at each outlet / connecting piece shall not be less than 6.

4. Do not make the surface mat fall off during operation. If there is any falling off phenomenon, the surface mat must be re pasted before operation.

5. When the tip of the copper needle of the spot welding machine is blackened, the black spot of the copper needle shall be smoothed with a filigree knife before spot welding.

6. In case of any abnormality such as smoke and abnormal noise, turn off the power switch in time, stop the operation of the machine and instrument, and report to the superior supervisor.

Longtaich(www.longtaich.com ,

sales@longtaich.com,) manufacture and sell:

1. Resistance micro battery spot welder, E-bike battery pack welder, Power tool battery pack welder, Drill battery spot welder, Self balancing scooters battery pack welder, battery pack welder, Battery tabs spot welder, Battery nickel strips welder, Battery testing equipment, 18650, 26650, CR2032 battery cells, lithium battery, AAA battery, D-cell battery, Ni-MH battery, Ni-CD battery, battery welding pure nickel strips and tabs, battery accessories. etc.

Hits: 【Print】

Deutsche

Deutsche Español

Español français

français italiano

italiano português

português 日本語

日本語 한국어

한국어 العربية

العربية русский

русский bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt